- This topic has 12 replies, 2 voices, and was last updated 5 years ago by

Scudie.

-

AuthorPosts

-

-

3 April 2019 at 22 h 29 min #46110

Scudie

ParticipantWondered if any one had come up with a fix for broken plastic teeth on a Seeburg SC page unit ?

Unfortunately One of mine has a couple of dodgy teeth on one of the pages.

Cheers Scudie

-

4 April 2019 at 6 h 09 min #46111

Sooner

ParticipantSounds like it could be a challenge depending on how bad they are. I just repaired a page holder unit that had several problems. One problem was one of the fingers had a tooth where a small part of the tip was bent over. That caused it to bind so the page wouldn’t drop down. I trimmed the damaged part off and it works okay now.

-

4 April 2019 at 6 h 22 min #46112

Sooner

ParticipantIf they’re really bad I would probably remove the damaged part and then try making a mold and filling it with epoxy.

-

4 April 2019 at 23 h 53 min #46113

Scudie

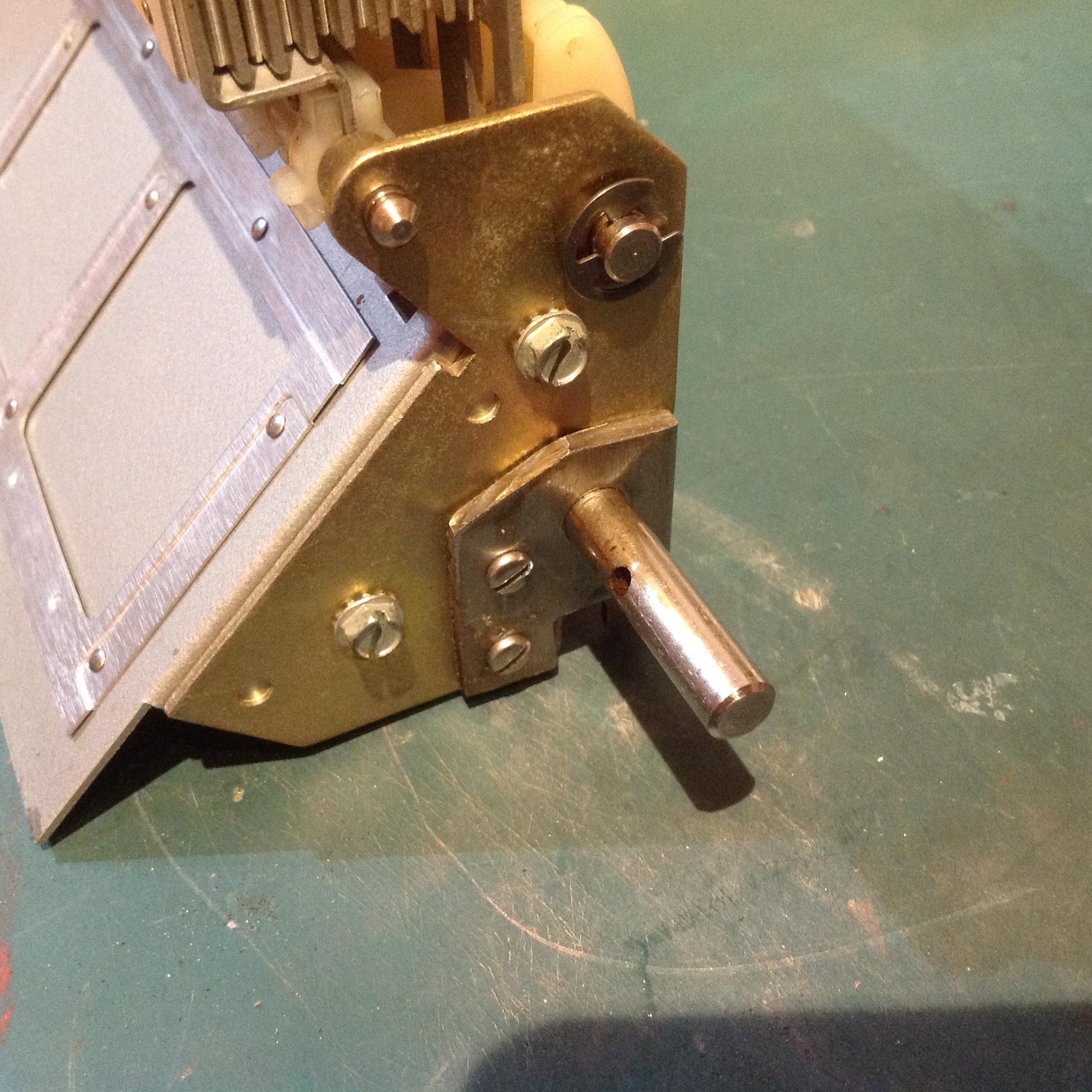

ParticipantHad a look at it tonight it’s the teeth on the back gear, not the one fixed to the page.

found some powder stuff that sets like plastic when sprinkled onto wet super glue, so have built up the area where the two damaged teeth are and will have a go at filing some new teeth out of it. If it doesn’t work will have a go at casting one out of epoxy resin.

Cheers Scudie

-

5 April 2019 at 21 h 13 min #46114

Scudie

ParticipantHave had a go at cutting two new teeth, it looks promising so far.

I think they will require a little extra shaping but so far so good. I had emailed a contact in the states to check on availability, he does have some $8 each plus shipping. So if my repair fails I can get a replacement.

Cheers Scudie

-

5 April 2019 at 22 h 18 min #46115

Sooner

ParticipantGood to know there’s a backup plan.

-

7 April 2019 at 1 h 06 min #46117

Scudie

ParticipantWell so far so good, when I first reassembled the pages it was ok flipping the pages up but jammed when trying to drop them down. I had another go at the repaired teeth and also found that there was a lot of free play where the plastic teeth are riveted to the page, some had more ply than others, not sure if I have done the right thing but I have given the rivets a bit of manipulation which has taken out the play.

Also not sure how much pressure should be applied by the four springs so far I have adjusted them a little which seems to have improved the action of the pages.

Cheers Scudie

-

7 April 2019 at 3 h 01 min #46118

Sooner

ParticipantI had a similar problem with the pages jamming when they were turned down. In my case there were two problems. The first was that the fingers were squeezed really tight between the retaining washers. That caused a lot of friction so they didn’t drop very well. On my other (good) mechanism the fingers had a little bit of play. Just enough that there was no friction caused by the adjacent fingers. The other problem was the gear with the bent tooth was causing it to bind and not drop down. The four springs on the back help push the pages forward so they come down. Adjusting those to press harder against the finger will help with those four pages but not the others.

The third problem with mine was that they wouldn’t stay all the way up properly when the last few pages were turned up. They would lean forward and cause it to jam when trying to turn them down. One issue was that the hole in the side where the selector rod goes through was worn so there was about 1/16″ of play. That kept the cam on the selector rod from pressing against the fingers far enough. I fixed that by bolting a backup bushing to the side to hold the selector rod where it’s supposed to be. That made a big difference.

The other issue is a weak design with the cams on early versions. The “partial” cams on the early ones only hold a page up while it’a being raised. It stops holding that page up when the next page is raised. The newer “full” cams continue to hold a page after others are raised. This helps keep the pages from leaning forward particularly when several are turned up. Apparently they made adapter kits at one time as this was a common problem. Fortunately mine works now and I didn’t have to try and modify mine.

-

This reply was modified 5 years ago by

Sooner.

-

This reply was modified 5 years ago by

-

7 April 2019 at 11 h 33 min #46120

Scudie

ParticipantHi Sooner

Looks like my page unit with issues is an early one with partial cams, and yes the pages hang forward when you get to the last ones as they are lifted.

Thanks for the photos and explanation I will take a look at mine later to see if there is play in the main shaft, the rockers are moving fine on there shaft, and surprisingly the new teeth are holding up fine at the moment, I had half expected them to break off the first time I tried it. In my experience super glue does not work very well on some plastics.

I assume you had to remove one of the chrome knobs is it just a case of removing a roll pin ?

Cheers Scudie

-

7 April 2019 at 14 h 08 min #46121

Sooner

ParticipantYes but getting the pin out was the hard part. I broke a few drill bits trying to drill it out first. Eventually I got it out with a home made nail punch that I ground down to match the size of the pin.

-

8 April 2019 at 23 h 07 min #46123

Scudie

ParticipantOk so have now got the page unit to work to an acceptable level. There was wear in the end plate so have carried out a mod like in your photo, the pages now hold upright even when you get to the last two. I also noticed that one of the plastic rockers had a groove worn into it, where the cam acts against it, more superglue and magic powder sorted that out. Also noticed that on the shaft that the toothed rockers pivot on there are three e clips one on each end and one about half inch from the end, this on had a wavey spring steel washer between this inner e clip and the first rocker, thus holding pressure on the rockers. Does yours have the wavey spring washer?

Cheers Scudie

-

9 April 2019 at 0 h 33 min #46126

Sooner

ParticipantNice job! Yes mine both have wavy washers that press the rockers together. The problem on one of mine was that either the teeth were too wide or the grooves were too close together so there was a lot of friction between them. Strange. I can’t imagine that it ever worked properly that way. Someone must have mixed replacement parts at some point. I fixed mine by grinding several teeth so they were slightly thinner.

Were you able to salvage the pin that holds the knob on the shaft? If not, I found 1/8″ pop rivets fit well. I ground the top part of the rivets off and used just the shaft. Then a little epoxy to hold it in place.

-

9 April 2019 at 8 h 15 min #46128

Scudie

ParticipantYes the roll pin was fairly straight forward to remove and I was able to reuse it.👍

-

-

AuthorPosts

- You must be logged in to reply to this topic.